Engineering Calculations

BELT PULL AND HORSEPOWER CALCULATIONS

I. LIVE LOAD ON THE CONVEYOR:

A. Horizontal Conveyor: Summation of total load being conveyed.

B. Incline Conveyor: Live load on incline portion multiplied by the

sine of the angle of incline (see “Net Lift Chart”).

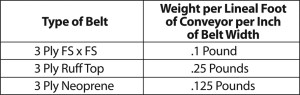

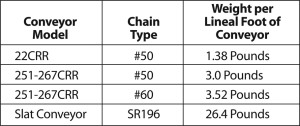

II. BELT OR CHAIN WEIGHT:

A. Belt Driven Conveyor: Belt weight from chart below multiplied by

the width of the belt multiplied by the length of the conveyor for

the weight of both the carrying belt and the return belt.

B. Chain Driven Conveyor: Chain weight from chart below multiplied

by conveyor length.

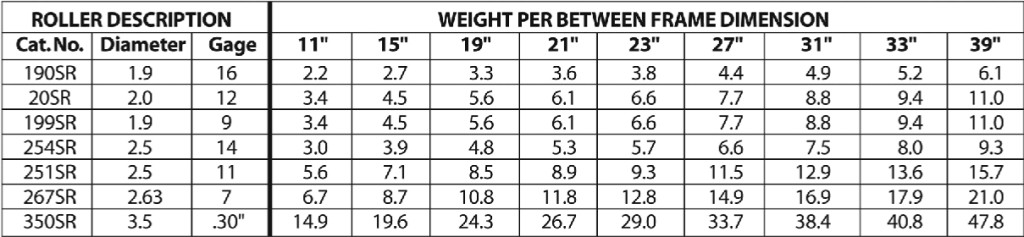

III. A. Roller Weight: See Chart below

III. B. Slat Weight: 1.95 pounds per lineal foot of conveyor per inch of

slat width.

IV. ADDITIONAL FACTORS:

A. Feeder Beds: 10% of the live load on the feeder bed.

B. Stopped product on running conveyor (case stop, traffic controller,

etc.): 10% of the stopped product.

C. Deflectors and Plows: 33% of the heaviest unit load.

V. COEFFICIENT OF FRICTION:

Slider Bed : .30; Belt on Roller : .05; Belt Driven Live Roller : .10;

Chain Driven Live Roller : .075; Slat Conveyor : .15;

Belt Pull Calculation: Summation of items I thru IV multiplied by item V;

Belt Pull = [(1A+II+III+ IV) x V]+1B

VI. EFFECTIVE BELT PULL:

Belt pull from item V multiplied by 1.25 equals effective belt pull.

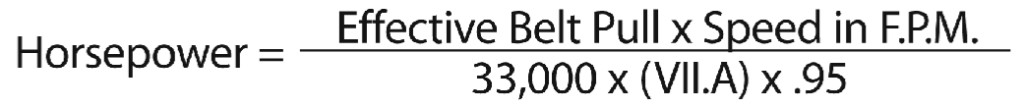

VII. DRIVE TRAIN EFFICIENCY FACTORS:

A. Gear Reduction: 100 minus one half of the ratio of each step of

reduction.

Example: Single Reduction 30: 1 Reduction

100 – 30/2 = 85% efficient.

Double Reduction 800: 1 Reduction

100 – 40/2 – 20/2 = 70% efficient.

B. Chain Reduction: 95% efficient.

Horsepower Calculation: Effective belt pull times speed in feet per

minute divided by 33,000 dived by the gear reduction efficiency

factor divided by the chain reduction efficiency factor.