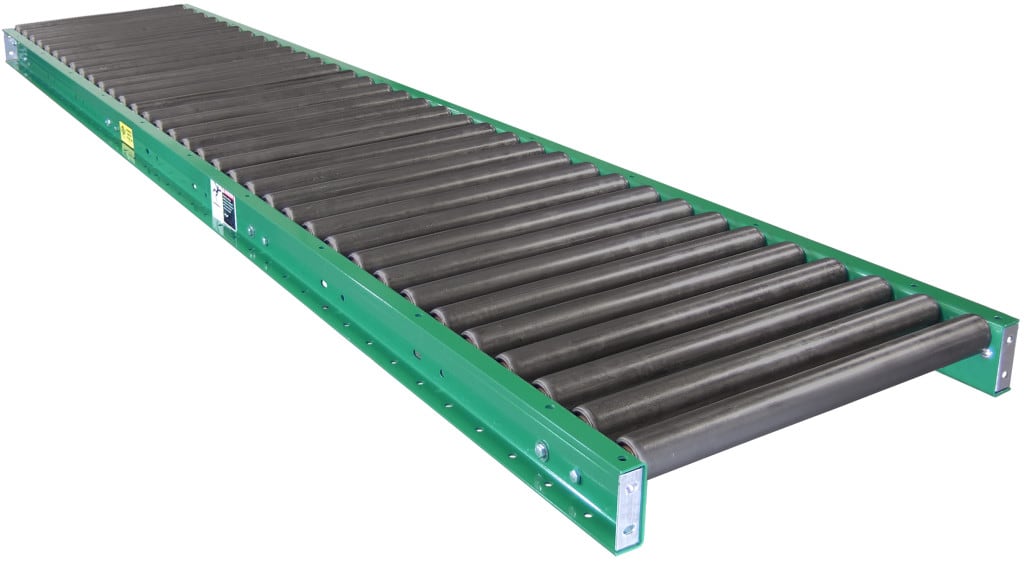

MODELS “251SR / 251SRC”

Gravity Roller Conveyors, Straight and Curved Sections

Applications / Features:

- Cartons

- Tote pans

- Assembly lines

- Shipping departments

Online Resources:

STANDARD SPECIFICATIONS

Frames– 4″ x 4 gauge steel channel with bolted cross members, powder painted. Rollers set 1⁄4″ high.

Rollers – 2-1⁄2″ x 11 gauge steel tubing with swaged bearings.

Bearings– Labyrinth sealed and grease packed.

Axles – 11⁄16″ hex shaft, spring-loaded.

Couplings– Splice plates, for bolting sections together.

Widths – 13″ between frames (B/F) and wider in two inch increments up to 27″ between frames;

also 31″, 33″, 37″, 39″, 45″, 51″, 55″ and 59″ between frames.

Lengths – 10′ and 5′ straight sections.

Curve Degree – 45° and 90° with 2′ 8-1⁄2″ inside radius for widths up to 27″ between frames.

4’0″ inside radius for 31″, 33″, 37″, and 39″ between frames. Tapered roller curve available.

Capacity – 650 pounds per roller with 3,750 pounds maximum distributed live load over 10 feet for 12″

nominal roll to 3,500 pounds on widest sizes; 8,000 pounds maximum distributed live load over 5′ lengths.

Curve sections same as 10′. All capacities based on 3″ centers.

(For Weight Specifications and Engineering Line Drawings please see catalog pages, above).

(Optional colors available at extra cost)