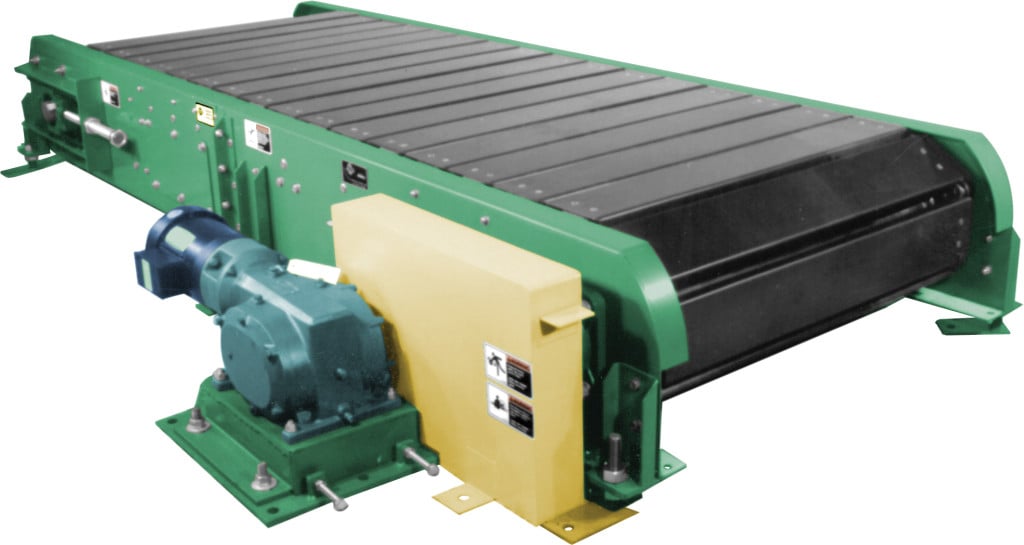

MODEL “SL”

Heavy Duty Slat Conveyor

Applications / Features:

- Packing

- Inspecting

- Assembling

- Testing

- Painting

- Heavy Duty Pallet Handling

Online Resources:

STANDARD SPECIFICATIONS

Slats – 5-3/4″ x 10 guage formed slat standard, bolted to A-2 attachments on chain. Slat length is effective conveying surface.

Conveyor Frame – Heavy duty, powder painted 7 gauge, bolted construction.

Chain & Slat Return – Returns on angle track, supplied as part of conveyor framework.

Chain – Heavy duty 6″ pitch with A-2 attachments on each pitch.

Driving Sprockets – 6 Tooth SR 196 12″ pitch diameter.

Floor Supports – Supplied as part of conveyor framework, not adjustable. Specify height. 24″ minimum elevation.

Drive Shaft – 2- 15/16″ diameter CRS.

Tail Shaft – 2-7/16″ diameter CRS.

Take-Up – Mounted on tail end of conveyor for adjustment of chain tension.

Drive – Floor mounted at discharge end of conveyor.

Speed – 30 FPM constant.

Reducer – Heavy duty worm gear reducer.

Motor – 2 HP 230/460-3-60 TE motor.

Capacity – 400 pounds per foot maximum. Not to exceed Load Capacity Chart (see catalog page).

(For Optional Equipment, Weight Specifications, and Engineering Line Drawings, please see catalog pages, above).

(Optional colors available at extra cost)

OPTIONAL EQUIPMENT

Slats – Heavier gauge and hardwood slats available.

Chain – 4″ pitch heavier duty chain available; inquire.

Dwell Station – Gravity section mounted level with slate surface. Allows product to be inspected,t ested, etc., while conveyor remains running.

Speed – Other constant speeds and variable speeds available.

Motor – Single phase, energy efficient, explosion proof, etc.Other HP available.

Electrical Controls – Magnetic starters, push button stations; manual motor starters with overload protection, others.