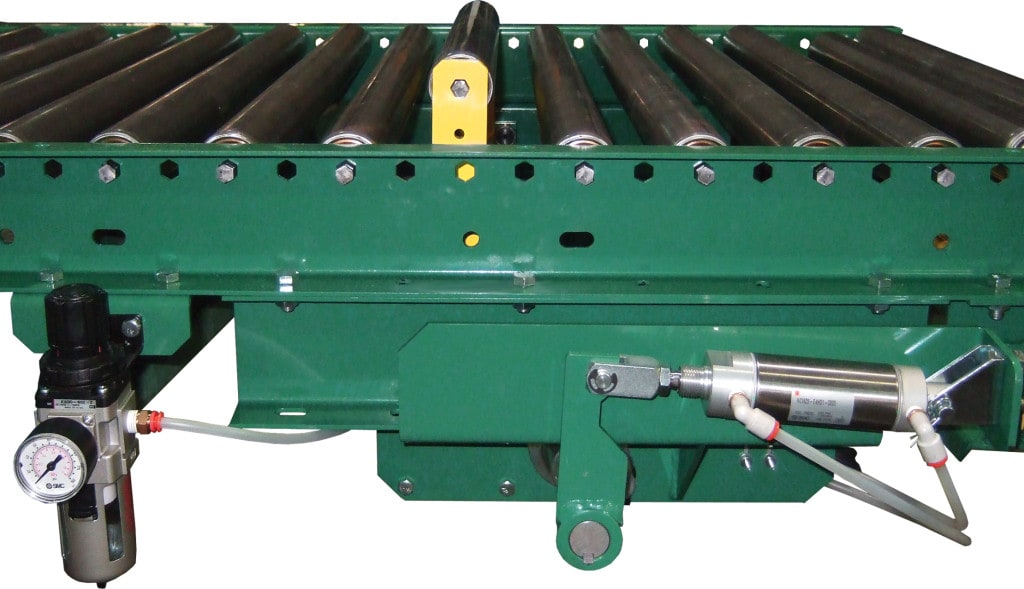

MODEL “Air Operated Blade / Roller Stop”

Air Operated Blade / Roller Stop

Applications / Features:

- Air Operated Stops are used where automatic line control is required such as assembly work stations, shipping areas, etc.

- Can be mounted to underside of models 138SR, 190SR, 20SR, 190CAP, 138CAP, 190ZPA.

Online Resources:

- Catalog Pages

- FAD

- Installation Manual

- Maintenance Schedule

- Product Warranty

STANDARD SPECIFICATIONS

Capacity– Blade -150 Ibs., 1-3⁄8″ roller – 50 Ibs., 1.9″ diameter roller -150 Ibs. All are live load capacities @ 60 FPM.

Bearings – High capacity (2) bolt flange bearings.

Stop – 1-3⁄8″ diameter x 18 gauge unplated steel roller for 1-3⁄8″ conveyors. 1.9″ diameter x 16 gauge galvanized steel roller for 1.9″ x 2.0″ conveyors.

Blade – 1⁄4″ steel plate.

Position– Supplied normally down. Can be supplied normally up specify.

Air Cylinder – 11⁄4″bore x 2″ stroke double acting air cylinder to raise or lower stop.

Air Requirements– Minimum pressure 60 PSI, maximum 100 PSI. Free air consumption @ 60 PSI – .014 cu. ft. per cycle, @ 100 PSI – .022 cu.ft.

Valve – Single solenoid 4 way valve. 1⁄4″ spring return- 20 NPT valve ports.

Electrical requirements– 120V, single phase, 60 Hertz. Current draw – .068 amps, or 24VDC.

(Optional colors available at extra cost)